Bow Bender Forming Press Rebuild

This customer manufactures a wide variety of School Buses and other Commercial Transportation Units. A.S.M.E., a division of Custom Rollform Products, manufactured a Coil Feed Rollform Line to punch, rollform, and cut-to-length a wide variety of Roof Trusses primarily for their School Bus Line. After rollforming the Roof Trusses they would put two lengths into an old Radius Form Press that would form them into a contour radius the height and width of the Bus.

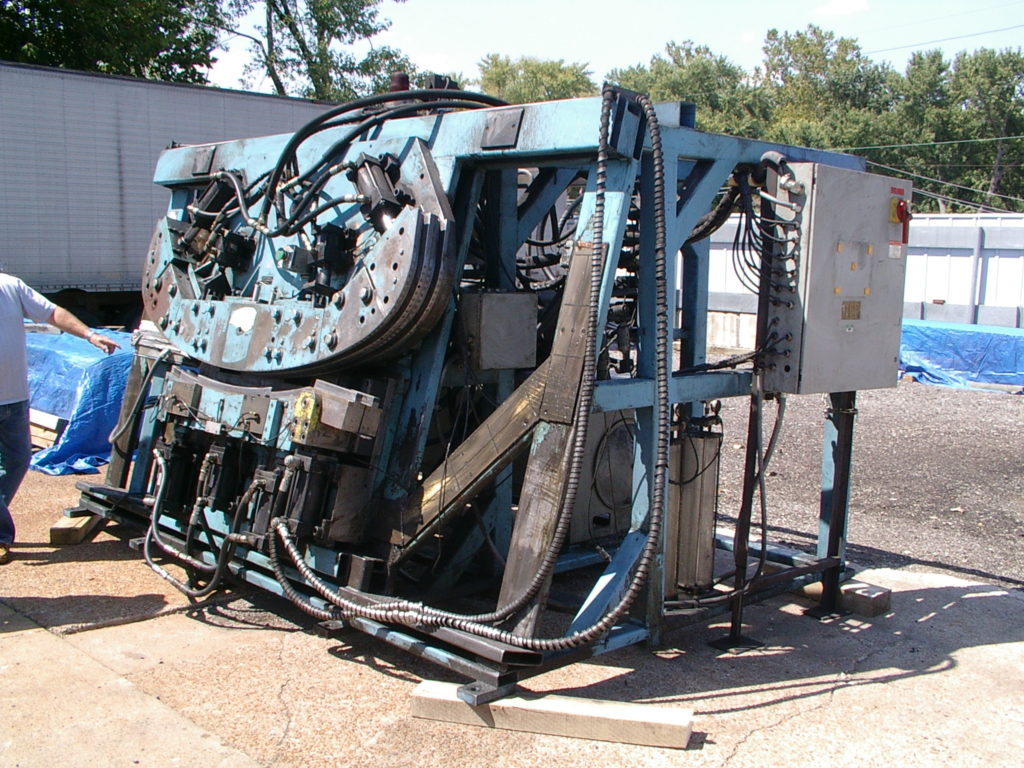

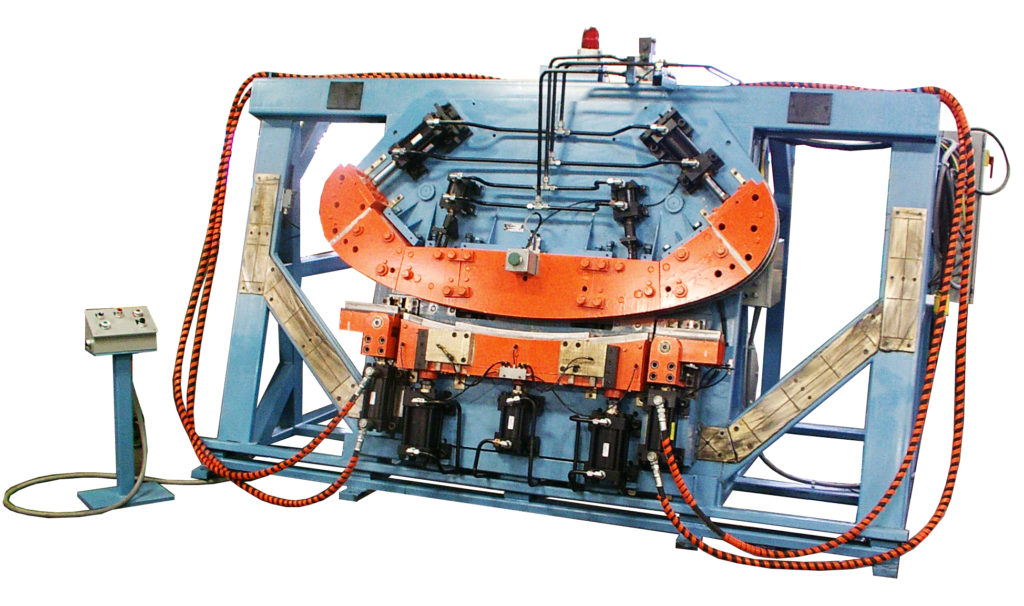

This unit was approximately 30 years old, and the manufacturer no longer built machinery. The machine design was a little unconventional but produced parts for years. The customer asked if we could rebuild the machine and update the Controls for them. The original frame was cracked and needed to be fixed and reinforced. All the Hydraulic Hoses, Cylinders, and Valves leaked and needed to be repaired or replaced. A lot of the Form Tooling, Bushings, and Guides needed to be reworked or replaced. A new PLC was added along with a lot of the Switches and Sensors.

We hard piped a lot of the Hydraulics and eliminated a lot of the Hoses and leakage problems.

It is not shown on the photo but we also built Safety Guarding for the System which was virtually non-existent before our rebuild.

Before

|

After |