|

Thank you for visiting the American Sheet Metal Equipment site. A.S.M.E., a division of Custom Rollform Products, has been producing top of the line Special Assembly Systems for over thirty years. We offer quality systems at a reasonable price. Our high standards keep our customers coming back.

Special assembly systems are designed to meet the specific needs of a particular product or application. They can be used to automate a wide range of assembly tasks, from simple to complex. Special assembly systems can offer a number of advantages over traditional manual assembly methods, including:

|

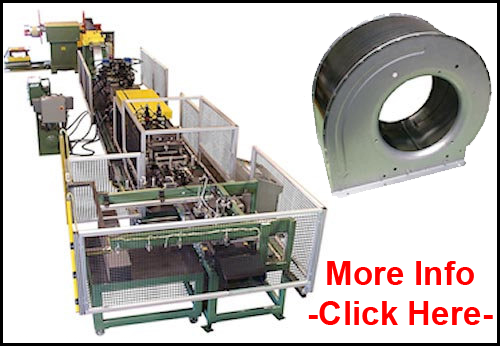

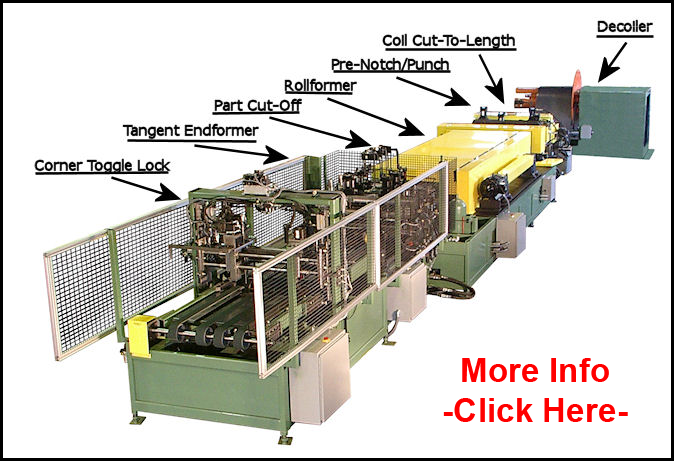

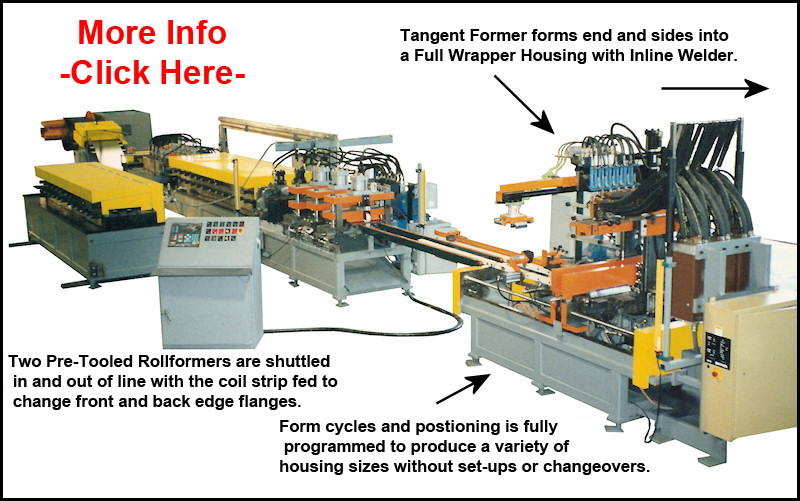

Pre-painted Furnace Cabinet System blank feed w/ eight position Stack Tower, Pre-Notch and Punch, Rollform and Programmable Tangent Wingform Endform three sided Wrapper Cabinet. |