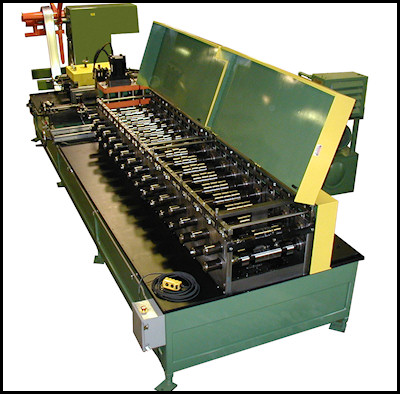

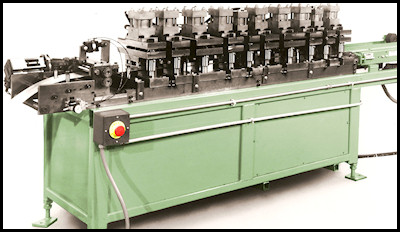

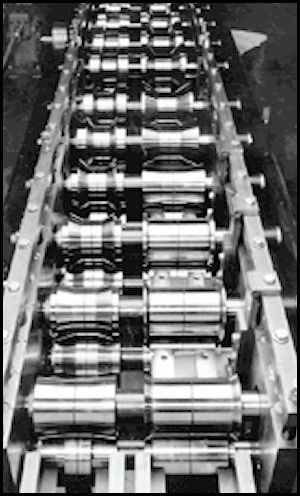

| ASME, a division of Custom Rollform Products, offers a wide range of Basic Rollformers to fit every profile and forming application. Additionally, all our Rollformers are Gear Driven and we design with Heavy Duty Bearings, Spindle Housings, and Roller Die Shafts.

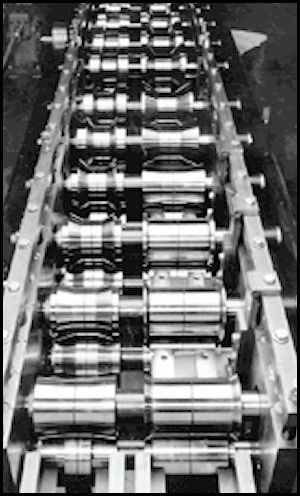

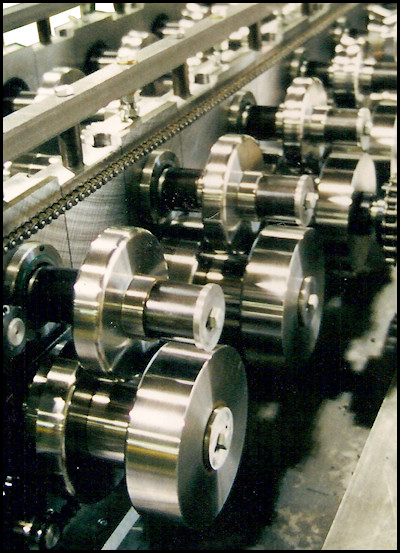

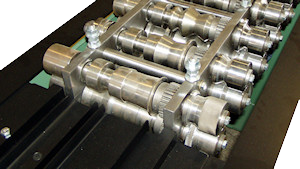

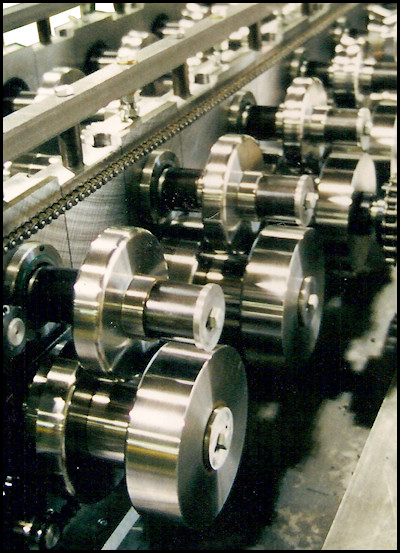

The Spindle Housings are precision ground and machined to exact specs. The Spindle Shafts are retained within quality machined Spindle Housings using heavy duty Timken style Roller Thrust Bearings.

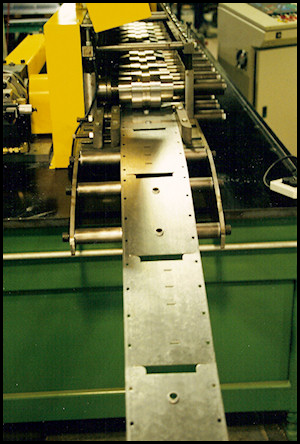

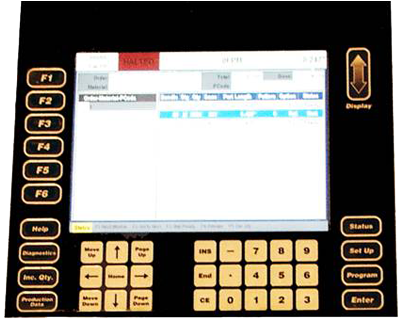

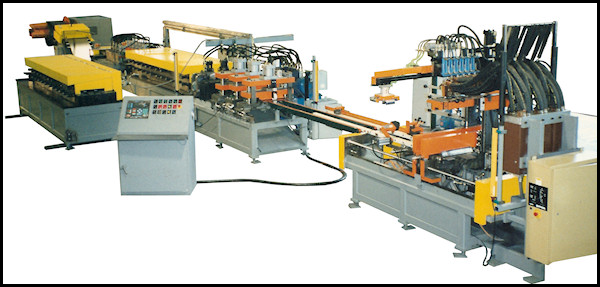

This Total On Time Production System allows you to run individual parts with a wide variety of lengths and patterns. Not only does this eliminate setups but downtime and / or scrap loss also.

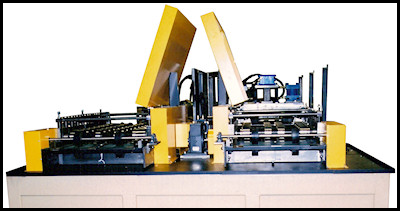

In our designs we try to understand the overall needs and requirements of our customers. Over the years we have designed and incorporated features that reduce set up and down time. Not to mention this allows greater flexibility in material and part variations, with greater accuracy and dependability. Overall, this System is just one example of the flexibility we offer. To point out the Rollform Tooling is changed from a simple Hand Wheel Lead Screw adjustment. It requires less than a minute to change from one part width to another.

|

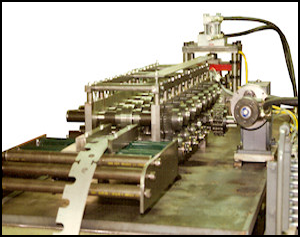

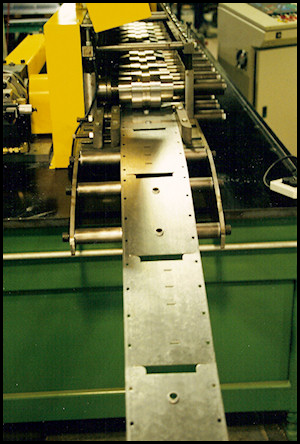

The Rollformer Feed Index (starts / stops) the strip through the Cut Off Press to minimize the set up or change over required for either length or width changes. |

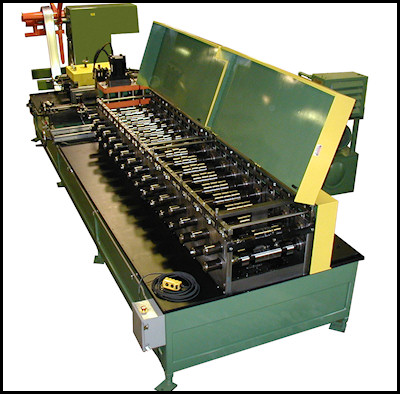

Inboard Application Forming Rolls on Inboard Spindles between the Bearing Housings. |

Rollforming

Rollforming is the art of progressively forming metal to produce a wide range of profiles and configurations. Another key point the part size, material, and profile determine the Roll and Shaft size, number of form stations, vertical and horizontal centers, Roll spacing, and horsepower. For example, improper Rollformer sizing can cause excessive stretching, bow, twist, ripples, and oil canning of the formed part. |

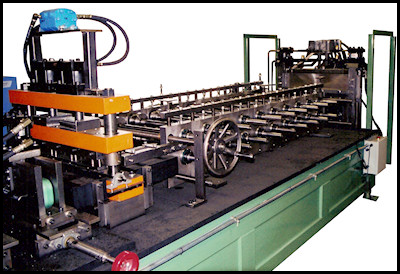

| A Rollformer can be set up with Inboard Tooling (Rolls between the Roll Shaft Spindle Bearings) or Outboard Tooling (Rolls on external extended Roll Spindles). Whenever possible, the part profiles should be run Inboard. In general, outboard applications should be for forming the edges of the metal on wide sheets. |

For example, this is Outboard Application Forming Rolls mounted on Outboard Extended Spindle Shafts that overhang from the Spindle Housing. This is primarily for edge form applications on wide sheets but can also form other profiles. |

Rollforming pre-notched, punched and embossed coil strip for full Wrapper Frames. |

Basic Rollformers

The basic Rollformer can be a manual blank feed form operation. It can also be inline to produce a complete Product Fabrication System. |

We make each Rollformer specially to match the part profile, material type, and overall production criteria.

What makes us different

To point out many Companies tend to overlook automation for Rollforming. This is due to the wide range of lengths, punch patterns, and end notching configurations required in their product. Moreover, our Engineers are solving these and many other production problems every day. Overall vast and dramatic changes and improvements have been made in all fields of electronics. For example, these changes include the types of Feeds and Index Drives along with major developments in Hydraulic and Pneumatic Controls. Hence the options are almost endless to any company aggressive enough to understand and utilize what is available today for the equipment of tomorrow.

The Rollformer can be pre-tooled with two sets of tooling (side by side) to form two independent part sections. Each section will have its own, separate Cut Off and Form Press. The entire Unit will be laterally shifted inline with the Coil Strip Feed when changing products.

We build Systems to increase productivity, minimize inventory and handling. To repeat the Systems are tailored to eliminate or minimize changeover of set up time. We provide quality systems at a price you can afford.