| Rollformers Home | Basic Rollformers | Variable Width Rollformers | Dual Head Rollformers | Independent Stand Rollformers |

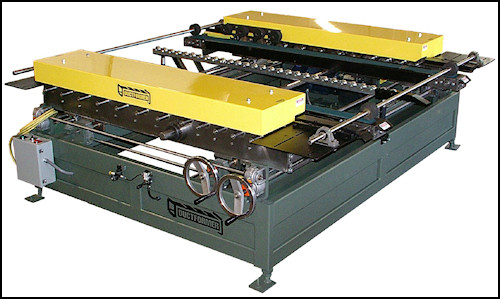

The use of the Dual Head Rollformer is to form two edges of the strip or part at the same time in a single pass through operation. For example the Dual Head Rollformer provides a quick changeover concept for parts needing a wide range of widths. It can be a free standing blank fed unit or adapted into a coil feed application. To point out a Dual Head is mainly used on edge forming operations needing straight parallel formed edges like shelving, cabinets, and wall panels.

The Rollformer consists of two parallel Rollform Head Assemblies (Spindle Housings) mounted on a common Frame and Drive with opposed Roll Tooling mounted on outboard extended Spindles. In other words the one Rollform Head is usually stays in place and the other is movable. A width change can range from approximately 6″ to 60″ with special applications as wide as 120″.

| Important to realize is not all Rollform companies can build a quality Dual Head Rollformer. We have over 40 years of design and application experience to build a high quality machine. |

The movable Head is usually on slides with Leadscrews to hold the Heads parallel across the full width range. |

As in all Rollform applications the part perimeters will determine the size, Centers, Spindles, and horsepower needed. With a Dual Head, the quality of the Spindle Housings (Forming Heads) is important. Equally important is the alignment and parallelism of the Heads and how the Slide and Drives are configured.

Benefits

Our Dual Heads are designed with additional Inboard Roll space which could be tooled with additional rollform profiles.

When you need multiple changes within the Dual Head edge form profiles, we offer a wide variety of quick changeover applications.