| Coil Cut To Length Lines Home | Compact Cut To Length | Double Slack Loop Cut To Length | Slit and Shear with Arbor Slitter | Programmable Slit and Shear Coil Line | CNC Notch / Punch Coil Cut To Length |

Compact Cut To Length Line

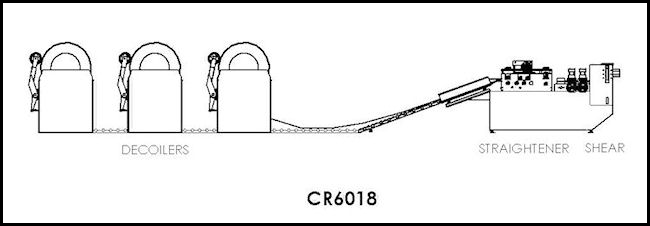

Model# C6018

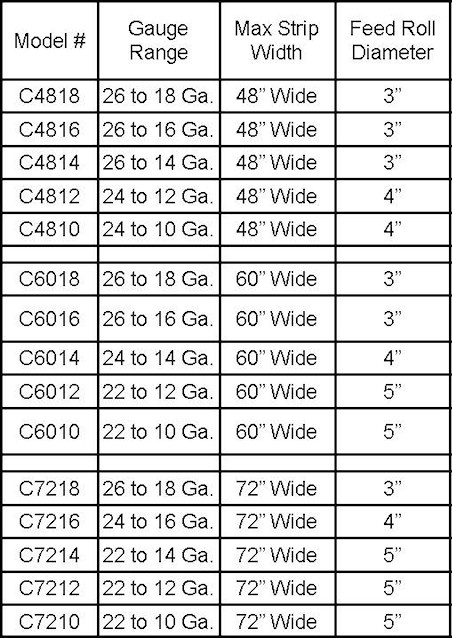

The Compact Cut To Length Line design and heavy duty construction makes this our most popular System. The Programmable Feed handles materials 26 gauge to 10 gauge up to 72” wide. Our wide range of Drives, Controls, and applications assures you will get the dependability and accuracy you expect from a quality System.

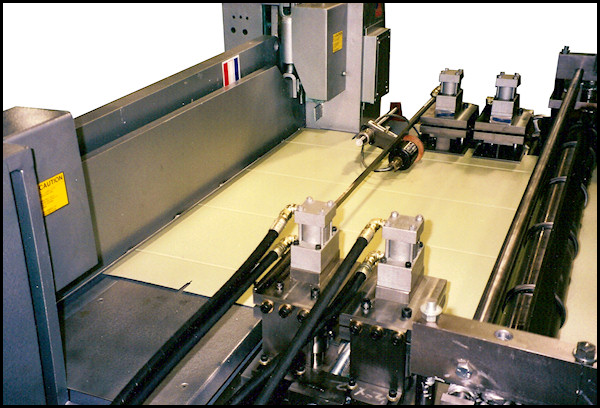

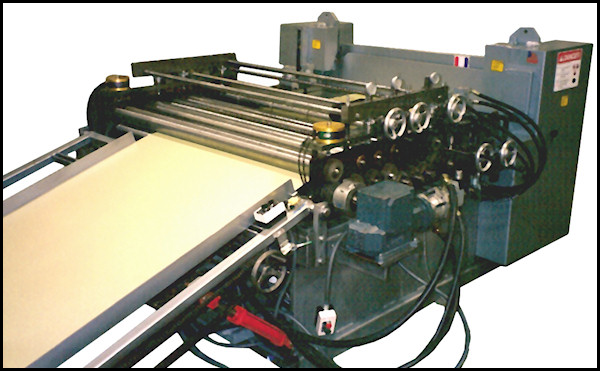

Cut To Length Line shown with 10,000# Decoiler under fed with optional Threader table.

Cut To Length Line shown with 10,000# Decoiler under fed with optional Threader table.

The Compact Cut To Length Line System features our quality Feeder Straightener and Shear Cutoff combined on a heavy duty all welded steel frame. We offer a wide range of Programmable Feed Drives and Controls for both Flying and Index Feed Applications.

Standard Features IncludeProgrammable Length and Batch Controls |

Options Available IncludeInline Notching and Punching |

Our standard design and components with standard Programmable Feed Length tolerance of ±.030 in 8’. Closed Loop or (Servo Feed) options available with ±.005” tolerance.

Here are some of the benefits of using cut-to-length machinery:

- Increased productivity: Cut To Length Machinery can help to increase productivity by cutting metal to specific lengths more quickly and efficiently than manual methods.

- Reduced waste: Cut To Length Machinery can help to reduce waste by cutting metal to specific lengths, which minimizes the amount of scrap metal that is produced.

- Improved quality: Cut To Length Machinery can help to improve the quality of metal products by cutting them to precise lengths, which reduces the risk of defects.

- Increased flexibility: Cut To Length Machinery can help to increase flexibility by allowing manufacturers to produce a variety of metal products with different lengths.

If you are looking for a way to improve your metal cutting process, then Cut To Length Machinery may be a good option for you.