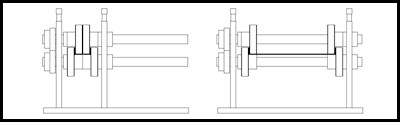

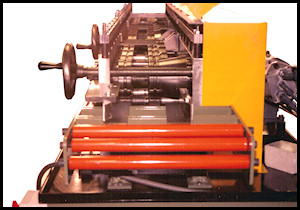

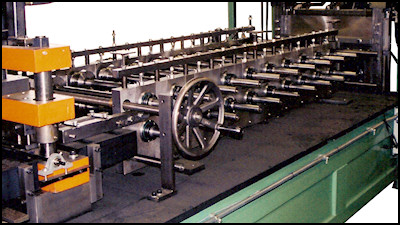

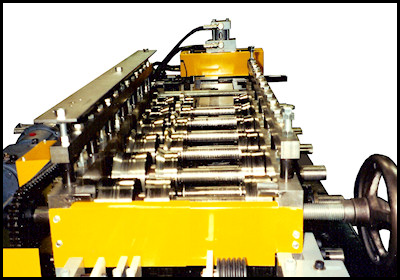

Variable Head Rollformers (Quick Changeover to Vary Roll Tooling and Part Profile)

| Rollformers Home | Basic Rollformers | Variable Width Rollformers | Dual Head Rollformers | Independent Stand Rollformers |

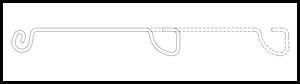

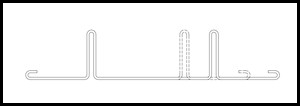

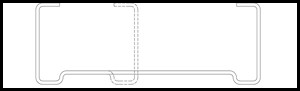

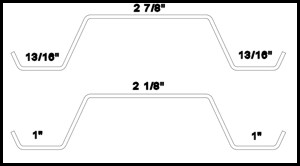

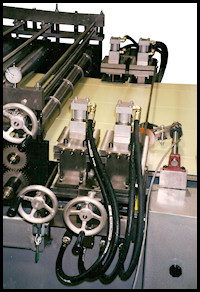

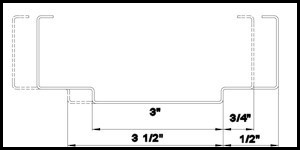

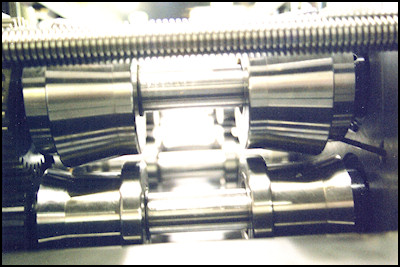

| One of our unique design concepts uses our Variable Width Quick Change Roll Tooling. The width of the tooling or part is changed with a simple Handwheel & Leadscrew setting. The Roll width setup can be performed in less than a minute. |

Variables can range from a few thousandths to around 20″ wide. Micrometer Readouts and Servo Positioning is available. |

|

See Video Click Here This eliminates hours of setup & change over time. A single Handwheel moves the complete Roll Set along the Bearing Housing Side Plate. |

| Leadscrews are positioned throughout the Rollformer to hold and retain the alignment. Infeed Guides, and Outfeed Straighteners are positioned at the same time in less than a minute. The width changes are infinite and can compensate for strip width. |  |

|

See Video Click Here |

|