Stiffener Rollform Line Refurbish

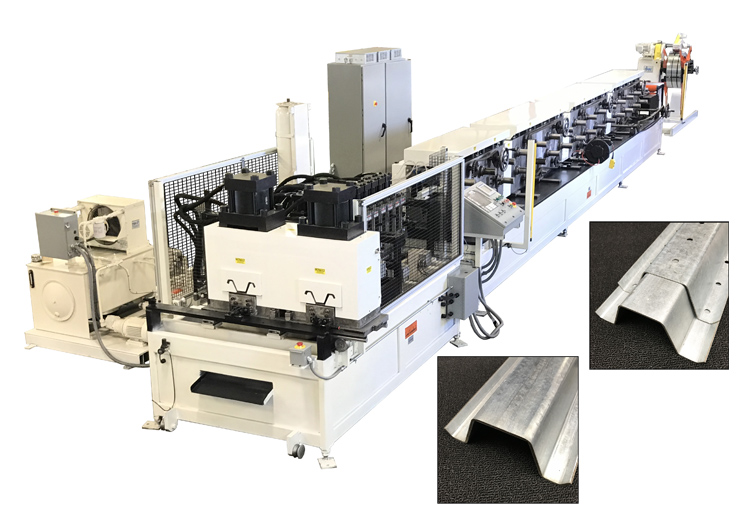

This is a Rollform Line we built twenty years ago to produce 7 Ga. to 16 Ga. Vertical Stiffeners for the Grain Bin Industry. The System featured our Pre-Tooled Variable Width Rollformer to make two similar profiles that would nest together in a quick change over application.

This machine was replaced for a heavier System that would also make Stiffeners up to ¼” thick. The customer wanted it rebuilt to be used again in their new venture overseas. Also, they wanted it upgraded with the latest Electronics, Drives, and Controls used to date.

The original Drive on the Rollformer was hydraulic and it held good accuracy through out its years of service. Today we use Variable Frequency Motors to drive our Rollformers. We do this especially when we need to hold tight tolerances on Index Feeds.

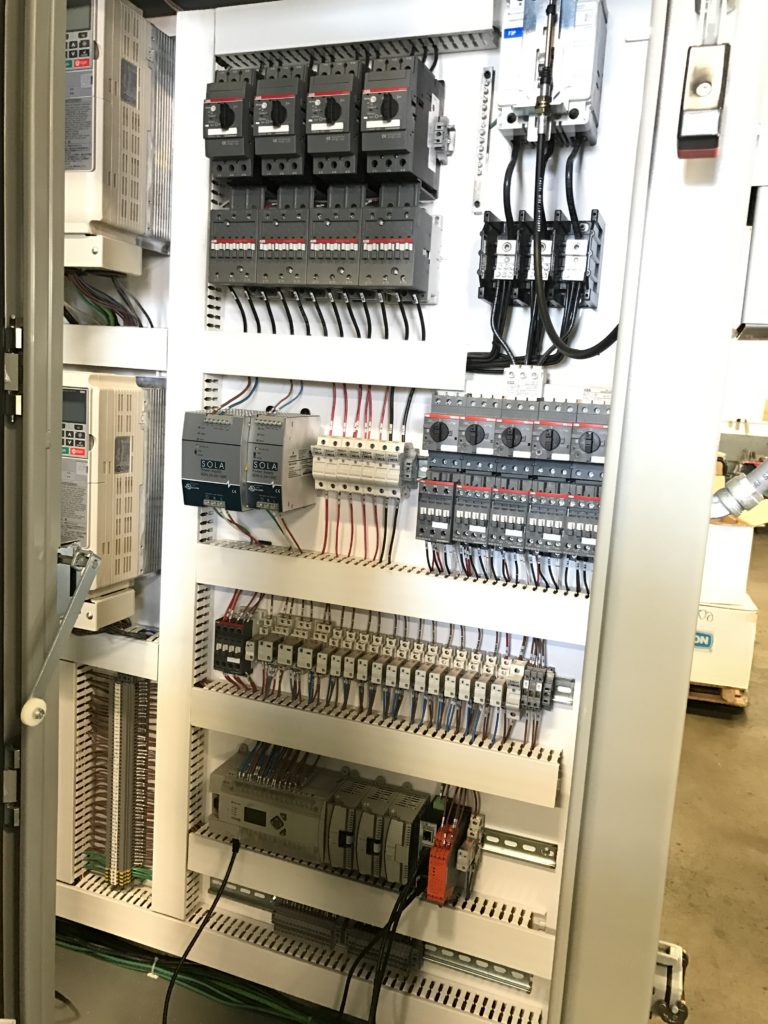

The rebuild and the modifications included building an all new Electronic Control Panel for the complete System. A new updated AMS Data Entry Controller was also added to the System. All the Hydraulic Cylinders were rebuilt or replaced, and we built a new Hydraulic Power Supply for the System. Every Bearing and the Bushing were checked out and / or replaced. All the Dies were rebuilt and / or modified.

All of the Safety Guarding, the Sensors, and the Light Curtains were modified or updated. This was to meet today’s current regulations.

This equipment was originally built by Custom Rollform Products, but we have rebuilt and made modifications to other types and brands of Sheet Metal Fabrication Equipment.

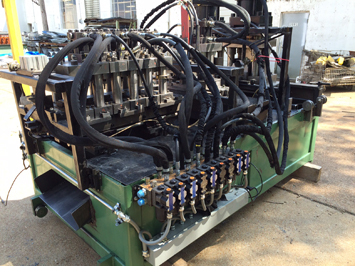

Before |

Prior |

Before |

After |

Before |

AfterNew Variable Frequency Motors and Reducers for increased Index Feed control. |

Before |

AfterComplete Rollform rebuild with new Guarding and Light Curtains |