ASME, a division of Custom Rollform Products, takes great pride in the designs and concepts we have introduced over the years to increase the productivity and accuracy of our Rollform Systems. We have led the field for over 40 years developing Programmable Index Feeds, Multiple Pre-Tooled Rollformers, Variable Width Rollform Tooling, and a wide variety of quick change tooling and setup concepts.

A Rollformer is a machine that uses a series of rolls to bend a long strip of sheet metal into a desired cross section. The rolls are on consecutive stands, and each stand performs only an incremental part of the bend. This allows for making a wide variety of profiles, from simple shapes like channels and angles to more complex shapes like corrugated roofing panels.

Rollforming is a versatile process that can be used to produce a wide variety of metal products. It is a cost effective and efficient way to produce high-quality metal products, and it is a process that is used in a wide variety of industries.

Advantages

Here are some of the advantages of using Rollformers:

- Rollformers can produce a wide variety of profiles.

- They are a cost effective and efficient way to produce metal products.

- They are used in a wide variety of industries.

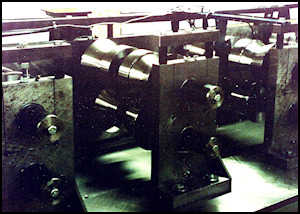

| Basic Rollformers

We offer a wide variety of Rollformers to fit every profile |

|

| Variable Width Rollforming Setup

One design incorporates our Variable Width Roll |

|

| Dual Head Rollformers (Duplex) (Panel Rollformers) The Dual Head Rollformer is designed to form two edges |

|

| Independent Stand Rollformers

Independent Outboard Stands support spindles and allow access |

|