| Tangent Formers Home |

Safes | Electrical Enclosure Boxes & Wireways |

Furnace Wrapper | Air-Conditioning Cabinets | Radius Corners |

Tangent Forming Three Sided Furnace Wrappers HousingsThis was a blank feed, punch and notch system feeding the part directly System sensed the length and width of the individual blank and automatically set the width of the notch, punch and Rollformer, then downloaded the feed sequence for the notch, punch and tangent form operations. |

Furnace Wrapper End Forming Front Flanges & Tangent Forming into three (3) sided Wrapper. 22 Ga. Pre-Painted |

Blank Feed System to Form the Furnace Wrapper Housing from Pre-Painted Mild Steel

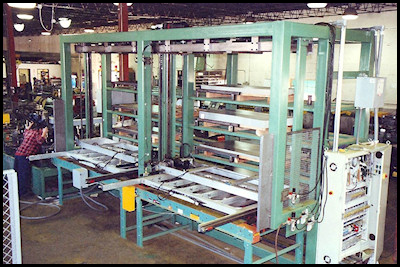

| The Double Stack Tower retrieved the pre-cut blanks from eight different skidded stacks. The parts will be placed onto the Feed Conveyor and transferred directly into the Pre-Notch and Punch Presses. |  |

Programmable Feed and Form Cycle to Produce a Three Sided WrapperTwo opposed programmable Tangent Formers using a combination feed form sequence will form a wide variety of three sided Furnace Wrappers. One traveling Tangent Former Head feeds and indexes the part into a fixed position Tangent Former Head. Using a combination of clamp, feed, and form cycles the two ends are formed then the sides are formed into a three sided Wrap Housing. Flange heights can vary from part without any changeovers or setups. |

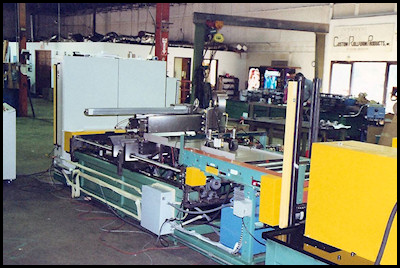

| The Punch, Notch, and Rollformer automatically varied in width to match the blank width. A program was downloaded to sequence the notch and punch pattern along with the form sequence for the Tangent Former. |  |

|

| The programmed Tangent Former accepted the part as it exits the Rollformer to form the two end flanges and form the units into a one piece three sided Housing. |  |