| Tangent Formers Home |

Safes | Electrical Enclosure Boxes & Wireways |

Furnace Wrapper | Air-Conditioning Cabinets | Radius Corners |

| A.S.M.E.. a division of Custom Rollform Products, makes a wide variety of Tangent Endformers and Wing Forming Units. They can be used as Free Standing Manual Feed Units or added into an Inline Fabrication System to final form the part.

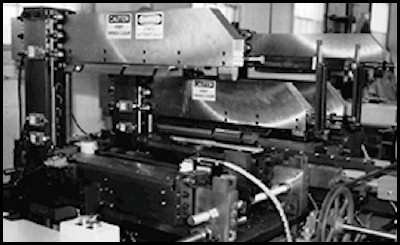

We make Tangent Endformers to Wingform or End Form Sheet Metal Flanges or Housings. This is while holding the part or panel in the horizontal flat panel position. They are Primary Free Standing Forming Units or to operate in conjunction with a Rollforming System to endform the leading and trailing ends and / or final form the part into a Full Wrapper Housing or Cabinet. |

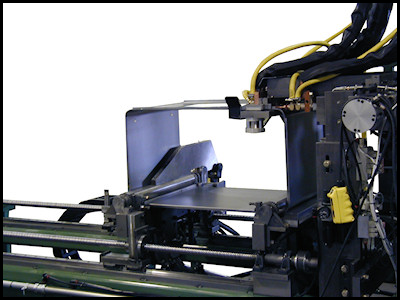

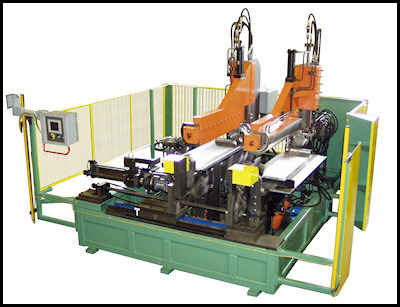

Forming Unit with Inline Welding |

Free Standing Tangent Wingformer 10 and 12 Ga. |

Tangent EndformerMany applications use a Rollformer to form the continuous linear flanges of a part and use a Tangent Endformer to close the end sections. Parts like Shelving, Partitions, Drawer Bodies, and Cabinets are just a few of the products that can use Tangent Forming Applications. Besides Endform Operations, Tangent Forming Units can also be used to final form sections into two sided, three sided, or four sided full wrapper cabinet sections. Items like Air Conditioners, File Cabinets, Refrigerators, or Vending Machine Cabinets can be formed in a variety of configurations. |

| In a Complete On Time Production System the Tangent Former can be completely sequenced and programmed. It would feed, form, and eject a variety of Cabinet configurations with little or no setup. It will form pre-rollformed Panels into final formed three sided Cabinets in five different depths, four widths, and two heights. The Outer Rams will form a 90° flange on both ends and the Inner Rams will form the Cabinet into a three sided Wrapper. The parts are fed directly from the Feed Conveyor, formed, then ejected sideways onto the next Conveyor to the assembly area. |

Tangent forming lead and trail ends then forming the part |